The world’s first production facility for protein made from thin air launched this week in Vantaa, Finland.

Finnish food tech Solar Foods said that Factory 01 – its first commercial-scale production facility of the company’s Solein product – represents commercialisation of the novel protein along with a possible look at the future of food production.

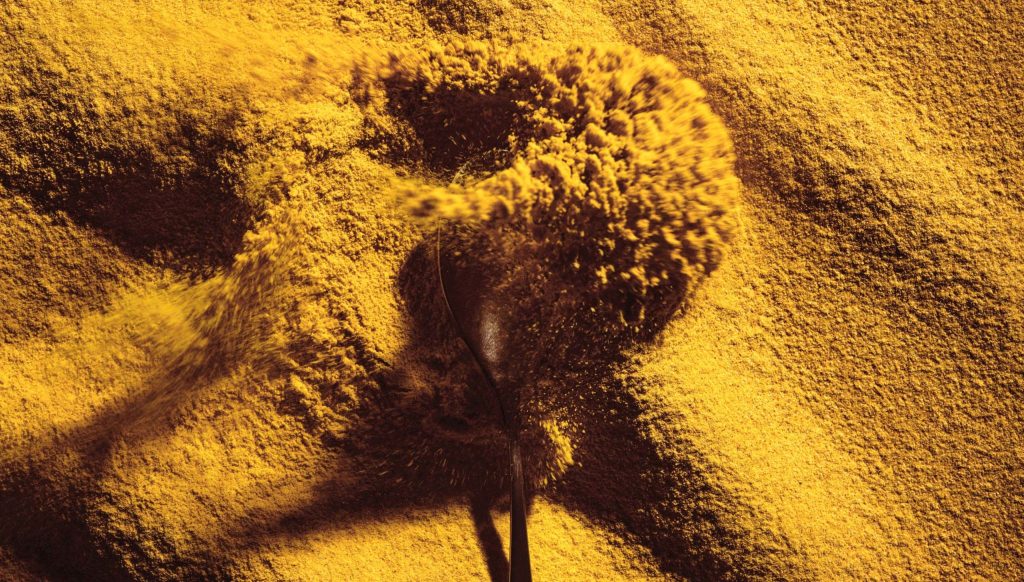

Solein is a food protein grown out of a tiny micro-organism with CO2 and electricity, similar to the way wine production uses sugar. Solar Foods said that up till now, the yellow powder – which can be used to replace proteins in foods such as alternative dairy and meat, snacks and beverages, noodles and pasta, among others – has been limited to small quantities produced in a pilot laboratory.

Solein received its first novel food regulatory approval in 2022 in Singapore, where it was used as the novel ingredient for limited-edition food products and test marketing, such as Solein-based snack bars and chocolate gelato. Solar Foods estimates Factory 01 will increase Solein’s annual production up to a maximum of 160 tons.

The company claims that Factory 01’s bioreactor grows the same amount of Solein protein per day as a 300-cow dairy farm would produce milk protein, while being entirely decoupled from the demands and environmental stresses of traditional agriculture. Solar Foods says Solein could be produced anywhere from deserts, to Arctic areas, and even in space.

Solein protein. Image via Solar Foods.

Solar Foods CEO and co-founder Pasi Vainikka said: “We will be able to deliver quantities that allow food producers for the first time to create large batches of Solein-powered products. While we have been able to offer consumers a small taste, finding a Solein-based food in your local supermarket has not been possible. Soon it will be.”

Vainikka describes the company’s milestone in food production to the impact quantum computing will have on information processing, saying, “Just like with quantum computers, it’s no longer a question of will cellular agriculture become a thing: it’s evident that it will. The question is more about who leads the charge.

“We are exploring the possibilities of this scientific platform on a new scale. Factory 01 demonstrates it is possible to grow protein from start to finish under one roof, year-round even in the harsh Northern conditions of Finland – and to do it all sustainably and in a commercially viable manner.”

Solar Foods says Factory 01 is also a part of the European hydrogen economy, the factory being the European Commission’s first hydrogen IPCEI project (Important Project of Common European Interest) to be completed.

The company also said that Factory 01 is a high-tech and highly automated facility, with the factory’s “farmers” to do most of their work in the facility’s control room rather than on the factory floor. The facility will also serve as Solar Foods’ hub for R&D and future product development as well as provide valuable data for the next milestone: Factory 02.

“Factory 01 is already a bona fide factory, the kind you could see in an industrial park. But to realise Solein’s full potential, we think bigger,” Vainikka explained. “That’s why Factory 02 will eventually scale up the bioprocess as well as the production process: it would not be located in an industrial park, it would more likely fill an industrial park.”

In May 2023, Solar Foods agreed on a strategic alliance to develop and test market Solein-based products in Singapore with the Japanese food giant Ajinomoto Group. The two companies are also looking to expand their cooperation to countries and regions beyond Singapore.

Solar Foods said it is seeking novel food regulatory approvals for Solein in several key markets, including the EU, the UK, and the United States. The company’s aim is to enter the US market in late 2024.

To stay up-to-date on the latest industry headlines, sign up to Future Alternative’s enewsletter.

Posted on: