Queensland University of Technology (QUT) and Australia’s Food and Beverage Accelerator (FaBA) are co-investing in the building of a facility to enhance production of novel food ingredients.

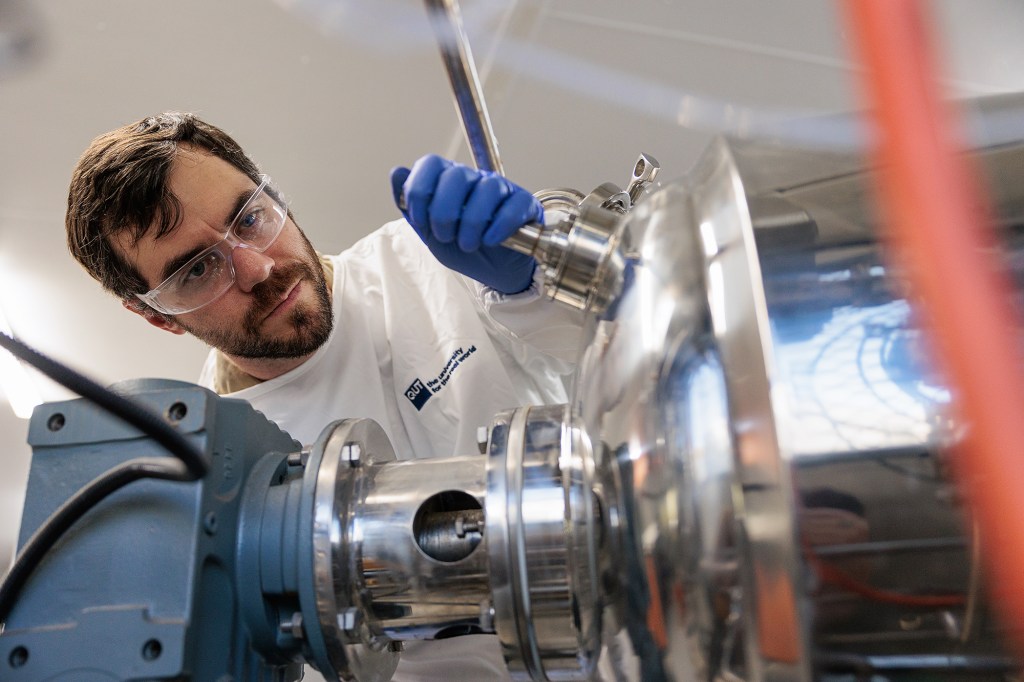

The $3.9 million project will complete the transformation of the QUT Mackay Renewable Biocommodities Pilot Plant (MRBPP) into a state-of-the-art food-grade compliant pilot facility.

Professor Ian O’Hara, who led development on the MRBPP over a decade ago, said the investment would significantly expand the facility’s capability and allow companies to fast-track product development in the F&B sector.

“This project is part of an overall $16 million upgrade to the facility to be completed this year which will transform the pilot plant into Australia’s leading physical containment level 2 (PC2) large scale food-grade research translation facility,” O’Hara said. “This will enable the production of novel food and beverage ingredients via precision fermentation and boost product development by providing a unique capability to undertake early-stage scale-up, reducing cost and timeframes for getting new products to market.

O’Hara added that precision fermentation in particular will allow Australia to produce new high-value food ingredients like proteins to boost the country’s bioeconomy and diversify exports for its agricultural and F&B industries.

Unlike traditional fermentation, which is used to make products such as beer and yoghurt, precision fermentation tunes microorganisms to produce specific enzymes, fats, or proteins at a large scale.

O’Hara said that although Australia has many of the ingredients for a successful precision fermentation ecosystem, such as expertise, the regulatory and business environment, and position in the Asia-Pacific region, the sector is being constrained by a global lack of scale-up infrastructure.

FaBA Director, Dr Chris Downs, said the Accelerator had invested in the pilot plant to address the scale-up issue and on-shore production of novel ingredients.

“The pilot plant has the potential to help cement Australia’s position as a leader in the development of ingredients from precision fermentation,” Downs said. “FaBA is delighted that we can invest with QUT to deliver this necessary infrastructure to help grow Australia’s food and beverage sector.”

Federal Assistant Minister for Education, Senator Anthony Chisholm, said FaBA’s investment in the facility would enable the industry to achieve its aim of doubling the value of Australia’s F&B manufacturing sector by 2030.

“New ingredients such as nutritionally valuable proteins and oils will not only give Australian consumers more choice on the supermarket shelf, they’ll also be better for the environment and made right here in Australia,” Chisholm said.

Launched in May 2023, FaBA is hosted by The University of Queensland, in collaboration with partners QUT, the University of Southern Queensland and UniQuest. It is supported by the Australian Government’s Department of Education through the Trailblazer Universities Program.

Australian alt protein businesses that invested in FaBA’s first round include All G Foods, Eden Brew, Nourish Ingredients and v2food.

To stay up-to-date on the latest industry headlines, sign up to Future Alternative’s enewsletter.

Posted on: